2026 Top Steam Control Valve Features You Should Know?

The steam control valve is essential in various industries, notably in energy and manufacturing sectors. According to a recent report by MarketsandMarkets, the global valve market is projected to reach $85.8 billion by 2025. This growth illustrates the increasing demand for efficient steam control systems.

Steam control valves play a critical role in regulating steam flow and pressure. Their performance directly influences system efficiency and safety. With advancements in technology, new features are emerging, enhancing control and precision. Modern steam control valves now offer better energy management solutions, contributing to sustainability goals.

However, industries often face challenges. Many existing systems may not integrate seamlessly with newer technologies. Additionally, the complexity of valve selection can lead to inefficiencies. Understanding the essential features of steam control valves can help mitigate these issues and optimize performance. Awareness of these aspects is vital for any operation relying on steam applications.

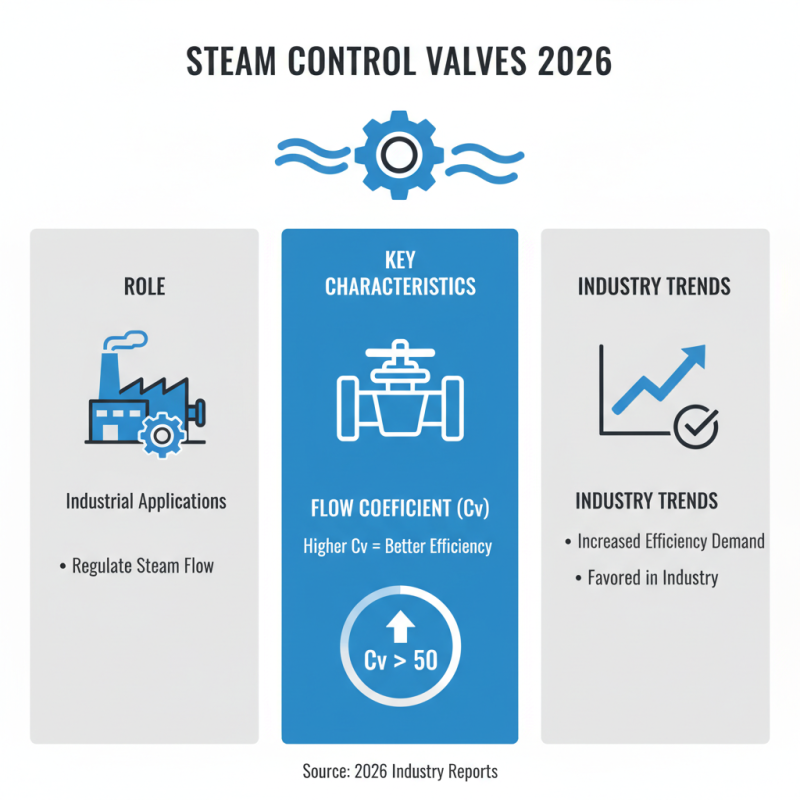

Key Characteristics of Steam Control Valves for 2026

Steam control valves play a crucial role in various industries, efficiently regulating steam flow. In 2026, several key characteristics distinguish high-quality steam control valves. One critical feature is the valve's flow coefficient (Cv). A higher Cv rating indicates better flow efficiency. According to industry reports, valves with a Cv above 50 are increasingly favored in industrial applications.

Another essential characteristic is the material used in construction. The best steam control valves often utilize stainless steel or high-grade alloys that can withstand high temperatures and pressures. These materials enhance durability and reliability. Reports from engineering publications indicate that 80% of steam control valve failures are due to corrosion or thermal fatigue.

Additionally, smart technology is becoming a standard feature. Many new valves now incorporate IoT capabilities. They allow for real-time monitoring and predictive maintenance. This shift aims to reduce downtime and enhance operational efficiency. However, integrating these technologies poses challenges. Companies must ensure proper training for personnel to maximize the benefits of smart systems. Regular assessments of system performance are also necessary to avoid potential pitfalls. These features collectively highlight the evolving landscape of steam control valve technology in 2026.

Innovative Technologies in Steam Control Valve Design

Innovative technologies are transforming steam control valves. Designers focus on enhancing efficiency and reliability. One key feature is the use of advanced materials. These materials withstand high pressure and temperature fluctuations. They also reduce wear and tear over time. This leads to longer lifespans for steam control valves.

Another noteworthy development is the integration of smart technologies. Wireless sensors monitor valve performance in real-time. Data analytics help engineers predict maintenance needs. This proactive approach minimizes downtime. Yet, not every system implementation works perfectly. Some users report challenges with system integration. Training staff on new technologies can also be an issue.

Compact designs are gaining popularity too. These valves fit in tight spaces without sacrificing performance. They are crucial in modern industrial applications. However, achieving the right balance between size and efficiency can be tricky. Designers must constantly innovate to meet evolving demands. The future of steam control valves looks promising but requires ongoing improvement and adaptation.

Importance of Material Selection in Valve Durability

Material selection plays a crucial role in the durability of steam control valves. Different materials can significantly affect a valve's performance and lifespan. For example, studies show that stainless steel valves can resist corrosion and wear better than their carbon steel counterparts. This translates to fewer failures and replacements, which is a significant cost-saving for industries.

Data from industry reports indicate that nearly 30% of valve failures are attributed to improper material choices. For high-temperature applications, using materials that can withstand heat is essential. High-performance alloys or specially coated materials often enhance the longevity of the equipment. However, cost considerations can lead to suboptimal choices, resulting in more frequent maintenance.

Employing advanced materials can mitigate risks but might elevate initial costs. In some instances, a cheaper material could lead to higher repair costs over time. It's a delicate balance to strike. Companies must evaluate not just the upfront investment but also long-term performance. Ultimately, the right material choice is key to maximizing efficiency and durability in steam control valve applications.

2026 Top Steam Control Valve Features You Should Know?

| Feature | Importance | Material Selection | Durability Rating |

|---|---|---|---|

| Temperature Resistance | Essential for maintaining performance in high-temperature applications | Stainless Steel, Alloy Steel | High |

| Pressure Rating | Critical for safety and functionality under various operating conditions | Carbon Steel, High-Strength Alloys | Medium to High |

| Corrosion Resistance | Increases lifespan and reliability in harsh environments | Nickel Alloys, PVC Coatings | High |

| Fire Safety | Preventative feature to avoid accidents in flammable environments | Fire-Resistant Materials, Ceramics | High |

| Seal Quality | Ensures no leaks and maintains performance efficiency | EPDM, PTFE | Medium |

Understanding Flow Control Mechanisms in Steam Valves

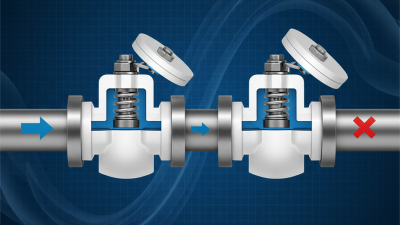

Steam control valves play a crucial role in managing flow in various systems. They regulate steam pressure and temperature, ensuring efficiency. Understanding the flow control mechanisms is essential for optimal performance.

A key feature of steam control valves is the actuator. It converts electrical signals into mechanical action. This allows precise control over the valve position. Proper calibration of the actuator can lead to better energy efficiency.

**Tips:** Ensure regular maintenance to prevent failures. Inspect seals and gaskets for wear. Check responsiveness during operation. Small issues can escalate if ignored.

Another important aspect is the valve seat design. It affects sealing performance and flow characteristics. A poorly designed seat can lead to leaks and reduced efficiency. Take time to evaluate your valve's design regularly.

**Tips:** Look for signs of wear or corrosion. Replace parts as required to maintain performance. Even minor imperfections can cause significant issues.

Understanding these features can help make informed decisions. Don’t overlook the basics. They can impact the entire system's efficiency and reliability.

Future Trends in Steam Control Valve Applications and Performance

In the realm of steam control valves, future trends are shaping applications and performance. Enhanced materials are emerging. These materials can withstand high pressures and temperatures. They ensure durability and maintain efficiency. Advanced designs incorporate smart technology. Sensors and automation contribute to more precise control.

Tips: Regularly inspect your steam control valves. Monitoring for wear and tear can prevent unexpected failures.

Energy efficiency is a key focus. As industries push for sustainability, steam control valves need to perform better. Reducing energy loss is essential in every application. Automation allows for real-time adjustments, optimizing performance continuously.

Tips: Consider retrofitting older systems. Upgrading can lead to significant performance improvements. Efficiency gains can justify the initial investment.

Emphasizing safety cannot be overlooked. As systems become more complex, rigorous safety standards are vital. Proper training for operators is necessary. They must understand how to manage new technology effectively.

Tips: Always provide training sessions for staff. Regular refreshers can improve overall safety in operations.

Related Posts

-

5 Essential Tips for Choosing the Right Lined Valves for Your Industrial Needs

-

What is a PTFE Lined Check Valve and How Does it Work in Fluid Systems

-

Understanding Industry Standards for the Best Actuator Valve and How to Choose the Right One

-

Unlocking Efficiency: How Ball Valve Actuators Revolutionize Industrial Automation Systems

-

Mastering BFV Valves: A Comprehensive Tutorial on Selection, Sizing, and Optimization Techniques

-

Common Issues Faced by Global Buyers When Sourcing Gas Valves: A Comprehensive Guide