What is a Check Valve and How Does It Work in Fluid Systems

In fluid systems, the efficient regulation of flow is crucial for optimal performance and safety. One essential component that plays a significant role in this process is the check valve. A check valve is a mechanical device designed to prevent backflow in a piping system, ensuring that fluids flow in one direction only. This functionality is vital in numerous applications, including water supply systems, heating systems, and industrial processes. Understanding how a check valve works can help engineers and technicians design and maintain more effective fluid systems. In this article, we will explore the basics of check valves, their operation principles, and provide useful tips for selecting and installing them in various applications. By the end, readers will have a solid foundation on check valves, enabling better decision-making in their fluid system designs.

In fluid systems, the efficient regulation of flow is crucial for optimal performance and safety. One essential component that plays a significant role in this process is the check valve. A check valve is a mechanical device designed to prevent backflow in a piping system, ensuring that fluids flow in one direction only. This functionality is vital in numerous applications, including water supply systems, heating systems, and industrial processes. Understanding how a check valve works can help engineers and technicians design and maintain more effective fluid systems. In this article, we will explore the basics of check valves, their operation principles, and provide useful tips for selecting and installing them in various applications. By the end, readers will have a solid foundation on check valves, enabling better decision-making in their fluid system designs.

Definition and Purpose of a Check Valve in Fluid Systems

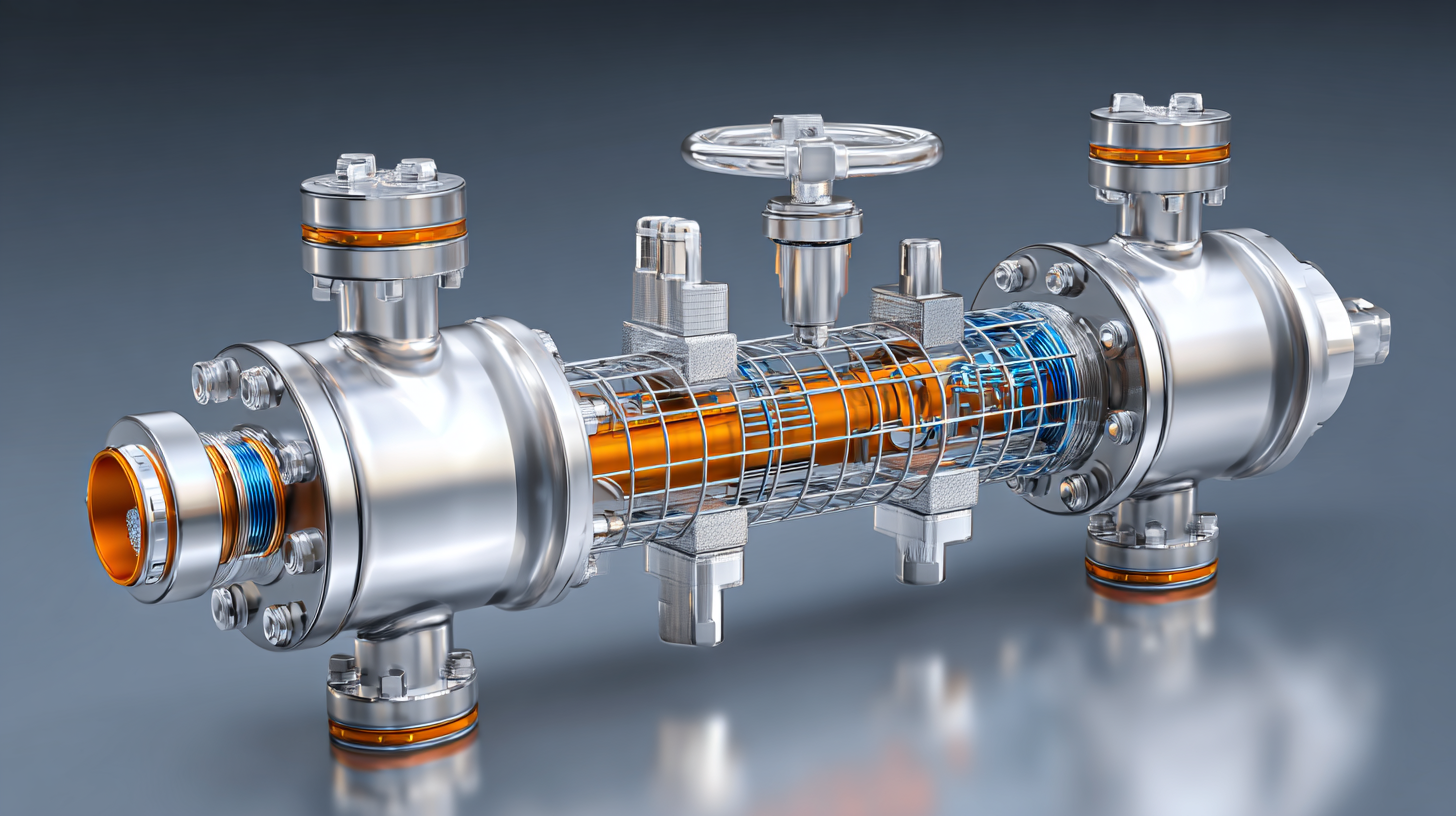

A check valve, also known as a one-way valve, is a crucial component in fluid systems designed to allow fluid to flow in one direction while preventing backflow. The primary purpose of a check valve is to ensure the integrity of the system by maintaining the intended flow path and protecting equipment from potential damage caused by reverse flow. By automatically closing when the fluid attempts to reverse direction, check valves help to maintain pressure and prevent contamination in various applications, from water supply systems to industrial processes.

A check valve, also known as a one-way valve, is a crucial component in fluid systems designed to allow fluid to flow in one direction while preventing backflow. The primary purpose of a check valve is to ensure the integrity of the system by maintaining the intended flow path and protecting equipment from potential damage caused by reverse flow. By automatically closing when the fluid attempts to reverse direction, check valves help to maintain pressure and prevent contamination in various applications, from water supply systems to industrial processes.

In fluid systems, check valves are typically placed at strategic points, such as in pipelines and pump discharge lines. They are available in various designs, including swing, lift, and ball types, each suited for specific operational requirements. The choice of a particular check valve type depends on factors such as the nature of the fluid, flow conditions, and the pressure levels within the system. Overall, the incorporation of check valves is essential for enhancing the efficiency and reliability of fluid systems, ensuring smooth operations without the risk of backflow-related issues.

Basic Operating Principles of Check Valves

A check valve is a crucial component in fluid systems, designed to allow fluid flow in one direction while preventing backward flow. The basic operating principle of a check valve relies on a mechanical mechanism that responds to differential pressure. When the fluid flow is in the correct direction, the pressure pushes the valve’s disc or ball away from the seat, allowing fluid to pass through. However, when the flow reverses, the pressure drops, and the valve closes, sealing off the system and preventing backflow.

Industry data shows that check valves play a vital role in various applications, including water treatment, oil and gas, and chemical processing. According to a report by Market Research Future, the global check valve market is projected to reach approximately $4.49 billion by 2027, reflecting a compound annual growth rate (CAGR) of around 5.4% from 2020. This growth can be attributed to the increasing demand for effective fluid control systems across different industries. Properly functioning check valves are essential for maintaining system efficiency and preventing costly leaks and equipment damage, underscoring their importance in fluid management.

Check Valve Flow Rate Analysis

This bar chart illustrates the flow rate of a check valve under different pressure ranges (in PSI). It highlights the performance characteristics and can help in understanding how check valves operate under varying conditions.

Common Types of Check Valves and Their Applications

Check valves are essential components in fluid systems, allowing flow in one direction while preventing backflow. Various types of check valves cater to different applications, each with unique features suited for specific tasks. For instance, the swing check valve operates with a hinged disc that swings open under forward flow and closes automatically when the flow reverses. This type is commonly used in gravity-fed applications and water supply systems.

Another popular type is the diaphragm check valve, which utilizes a flexible diaphragm to open and close the flow path. This design is ideal for applications involving slurries or corrosive fluids, as it minimizes wear and potential leaks. Additionally, spring-loaded check valves offer precise control and faster response times, making them suitable for high-pressure systems such as hydraulic installations.

Tip: When selecting a check valve, consider factors such as the fluid type, pressure, and required flow rate, as these elements influence the valve's performance and longevity. Regular maintenance and inspection are also crucial to ensure optimal functionality and prevent system failures.

Factors Influencing Check Valve Selection and Installation

When selecting a check valve for fluid systems, several critical factors must be considered to ensure optimal performance and reliability. One key factor is the type of fluid being transported; for instance, corrosive fluids may necessitate valves made from specialized materials, such as PVC or stainless steel, to prevent degradation. According to a report by the American Society of Mechanical Engineers (ASME), understanding the specific fluid characteristics, including temperature and pressure conditions, is essential in selecting the appropriate check valve design.

Additionally, the flow rate and the potential for backflow must be evaluated. According to the Hydraulic Institute, check valves must be sized correctly to minimize pressure drops and maintain efficiency, with up to a 15% loss in system efficiency noted in improperly sized valves. Installation location also plays a role; the valve should be positioned vertically or horizontally as prescribed by manufacturer guidelines to prevent operational issues. These considerations collectively impact the valve’s performance, longevity, and overall system integrity, highlighting the importance of a careful evaluation during the selection and installation process.

What is a Check Valve and How Does It Work in Fluid Systems - Factors Influencing Check Valve Selection and Installation

| Dimension | Description |

|---|---|

| Type | Swing Check Valve |

| Material | Stainless Steel |

| Pressure Rating | 150 PSI |

| Temperature Range | -20°F to 400°F |

| End Connections | Flanged |

| Application | Water Systems |

| Installation Position | Horizontal or Vertical |

| Maintenance | Minimal, periodic inspection |

Maintenance and Troubleshooting of Check Valves in Systems

Check valves are essential components in fluid systems, ensuring that fluid flows in one direction while preventing backflow. However, like any mechanical device, they require regular maintenance and can encounter issues over time. To ensure optimal performance, it’s important to establish a routine check-up schedule, which includes inspecting the valve for any signs of wear, leaks, or damage. A thorough cleaning can also help maintain its efficiency, removing any debris or buildup that may hinder its operation.

Troubleshooting check valves involves identifying common issues such as chatter, leakage, or failure to open. Chattering can often be resolved by adjusting the installation angle or ensuring that the pressure differential across the valve is adequate. Leakage may indicate wear on the seat or seals, necessitating replacement parts. Additionally, if a check valve fails to open, it may require inspection for blockages or sufficient upstream pressure. Addressing these problems promptly not only extends the lifespan of the check valve but also enhances the overall reliability of the fluid system.

Related Posts

-

Mastering Ball Valve Selection: A Comprehensive Tutorial for Optimal Flow Control in Industrial Applications

-

Understanding the Importance of Air Valve Types in Industrial Applications

-

Ultimate Checklist for Choosing the Right PTFE Valve for Your Industrial Needs

-

5 Essential Tips for Choosing the Right Lined Valves for Your Industrial Needs

-

How to Choose the Right Industrial Valves for Your Manufacturing Needs

-

Understanding the Functionality of Ball Check Valves in Fluid Control Systems