How to Choose the Right Flow Control Valve for Your System?

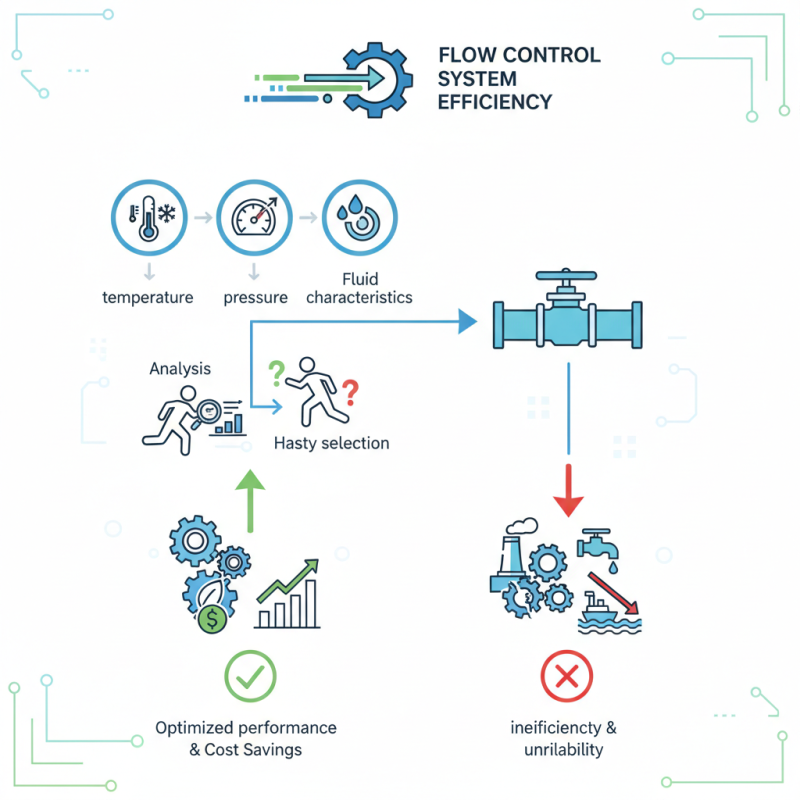

Choosing the right flow control valve is crucial for system efficiency. According to a recent report by the International Society of Automation, improper valve selection can lead to up to 30% energy waste. These valves manage the flow of liquids and gases in various applications, from industrial machinery to water systems.

Expert John Smith, a prominent figure in valve technology, states, “The right flow control valve can optimize performance, but many overlook the importance of data during selection.” His insight highlights a common issue; users often rush the selection process without sufficient analysis.

Different applications require different types of valves. Factors like pressure, temperature, and fluid characteristics play essential roles. Many practitioners ignore these details, leading to inefficiencies. Understanding how to choose a flow control valve can significantly impact system reliability and operational costs.

Understanding Flow Control Valves and Their Importance in Systems

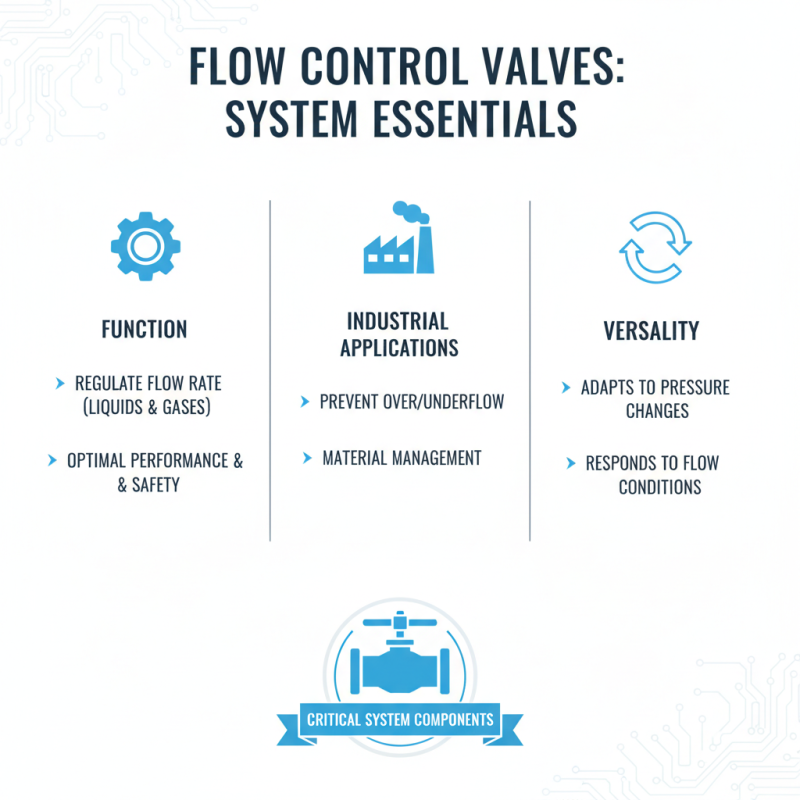

Flow control valves are essential components in many systems. They regulate the flow rate of liquids and gases. This regulation ensures optimal performance and safety. In industrial applications, these valves prevent overflow or underflow of materials. They can adapt to changing pressure and flow conditions, making them versatile.

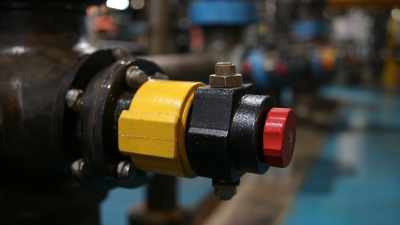

Understanding the types of flow control valves is vital. Each type serves a specific function. For instance, needle valves offer precise flow control, while ball valves provide quick shut-off. It’s important to assess the specific needs of your system. Do you require fine adjustments or quick responses? An improper choice can lead to inefficiencies and system failures.

Choosing the right valve requires a deep understanding of your system's requirements. Think about the fluid type, temperature, and pressure. Consider potential fluctuations during operation. Sometimes, users overlook maintenance needs. A neglected valve can lead to costly downtime. Envision the long-term impact of your choice. Reflect on how each option aligns with your system’s goals.

Types of Flow Control Valves and Their Applications

Flow control valves are crucial in various applications across industries. Understanding their types can help you make informed choices. According to a report from Markets and Markets, the global flow control valve market is projected to reach $14.1 billion by 2026. This highlights the increasing demand for efficient systems.

There are several types of flow control valves. Globe valves offer good throttling capabilities. They are often used in piping systems. They provide a balance between performance and cost. Butterfly valves, on the other hand, are compact. They can save space while still controlling flow effectively. This makes them popular in HVAC systems.

However, selecting the right valve is not straightforward. Sometimes, the wrong type can lead to inefficiencies. Deviations in specifications can cause overpressure or underperformance. Regular maintenance is also essential. According to a report by Technavio, improper maintenance can lead to a 30% reduction in valve life. Make sure to evaluate your system's specific needs and consider expert consultations before making decisions.

How to Choose the Right Flow Control Valve for Your System? - Types of Flow Control Valves and Their Applications

| Valve Type | Application | Advantages | Disadvantages |

|---|---|---|---|

| Gate Valve | On/Off Service | Minimal Flow Resistance | Not Suitable for Throttling |

| Globe Valve | Throttling and Flow Regulation | Good Flow Control | Higher Flow Resistance |

| Ball Valve | Quick Shut-Off | Durable and Reliable | Poor for Throttling |

| Butterfly Valve | Large Volume Flow Control | Lightweight and Compact | Limited Precise Control |

| Check Valve | Prevent Backflow | Automatic Operation | Limited Applications |

Key Factors to Consider When Selecting a Flow Control Valve

Choosing the right flow control valve requires careful consideration. There are several key factors that can significantly impact your system's performance.

The valve type is important. Different types handle fluids in various ways. For instance, some work best with liquids while others suit gases.

Pressure rating is another critical factor. Ensure the valve can handle the system's maximum pressure. An inadequate rating may lead to failures. Additionally, flow rate requirements must align with your needs. Too high or too low can affect efficiency.

Material compatibility is essential. The valve body must resist corrosion from the fluid. Incompatible materials can lead to leaks or premature failures. Size matters too, as improper sizing can cause turbulence and vibration, wasting energy. It’s easy to overlook these details. Skipping them might save time but leads to future frustrations.

Evaluating Specifications: Size, Material, and Pressure Ratings

When selecting a flow control valve, evaluating specifications is crucial. Size, material, and pressure ratings are key factors. The valve must match your system's dimensions. If it’s too large or too small, efficiency drops. Measure your pipes carefully. A mismatch can lead to leaks or performance issues.

Material choice affects durability and functionality. For example, metals resist high pressure, while plastics offer corrosion resistance. Consider the fluid type. Contaminated fluids require different materials. Always check compatibility. Inadequate material selection leads to unexpected failures. Remember, not all materials suit every environment.

Pressure ratings are essential for safety and reliability. They indicate how much pressure the valve can handle. Exceeding this limit can cause dangerous situations. Look for valves rated above your system's maximum pressure. This provides a safety buffer. Reflect on your system’s needs. Each choice impacts overall performance, highlighting the importance of thoughtful evaluation.

Flow Control Valve Specifications Comparison

Common Mistakes to Avoid When Choosing Flow Control Valves

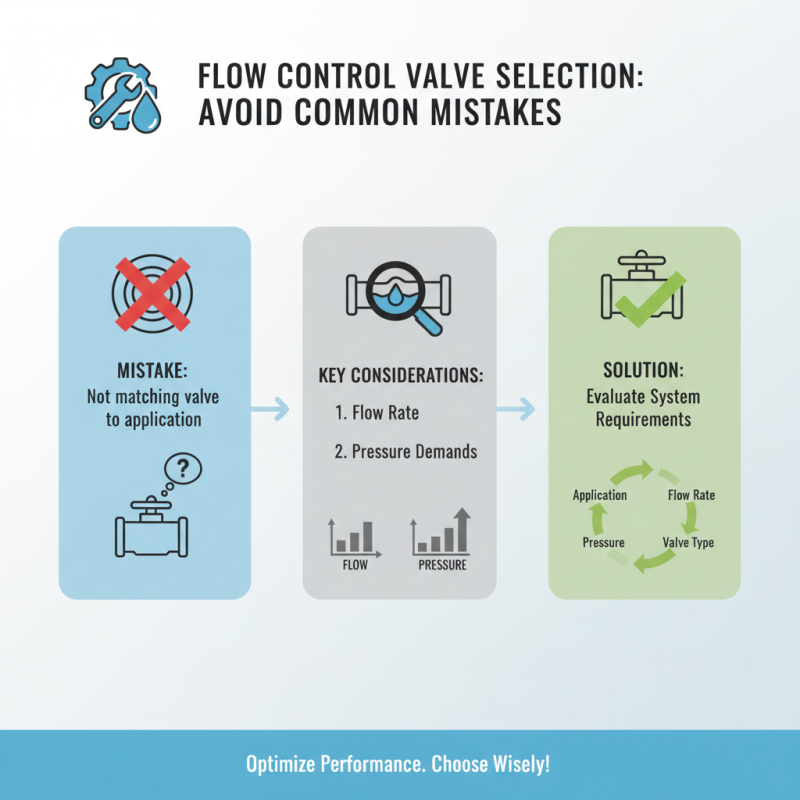

Choosing the right flow control valve can be tricky. Many make mistakes that affect their system's performance. One common error is selecting a valve without considering the specific application. Each system has unique requirements. It is crucial to evaluate the flow rate and pressure demands before making a decision.

Another mistake is overlooking the material compatibility. Flow control valves come in various materials. Using the wrong material can lead to corrosion and failure. Ensuring that the valve's material aligns with the fluid type is essential. Ignoring this can result in costly repairs and downtime.

Finally, it is vital not to rush the decision-making process. Many tend to select valves based only on price. This can be a flawed approach. A cheap valve might not have the longevity or reliability needed for your system. Taking the time to research options is worthwhile. A thoughtful approach leads to better performance and efficiency.

Related Posts

-

What is a Check Valve and How Does It Work in Fluid Systems

-

Common Issues Faced by Global Buyers When Sourcing Gas Valves: A Comprehensive Guide

-

How to Choose the Right Ball Check Valve for Your Industrial Applications

-

5 Essential Tips for Choosing the Right Lined Valves for Your Industrial Needs

-

2025 Top 10 Air Valve Innovations You Must Know About

-

Understanding the Importance of Pneumatic Ball Valves in Modern Industrial Applications