How to Choose the Right Lined Valves for Your Industrial Applications

In the complex landscape of industrial applications, selecting the appropriate lined valves can significantly influence operational efficiency and system longevity. According to Dr. Emily Foster, a leading expert in valve technology, "The right lined valve is not merely a component; it is a cornerstone that ensures the integrity and reliability of the entire process system." As industries continue to evolve, the demand for high-performance lined valves has grown, necessitating a deeper understanding of their unique characteristics and applications.

Lined valves are critical in applications where corrosion resistance and fluid containment are paramount. The materials used in their lining can drastically affect their performance, making it essential for engineers and procurement specialists to grasp the various options available. This profound selection process is not just about meeting standard specifications; it involves careful consideration of the specific conditions under which the valves will operate. By doing so, industries can safeguard against failures that disrupt operations and compromise safety.

Choosing the right lined valves is a strategic decision that transcends simple functionality. It intertwines with broader considerations such as cost-effectiveness, longevity, and compliance with industry standards. With expert insights and a structured approach, organizations can navigate the complexities involved in this selection, ensuring that they invest in solutions that offer optimal performance and reliability in their unique industrial contexts.

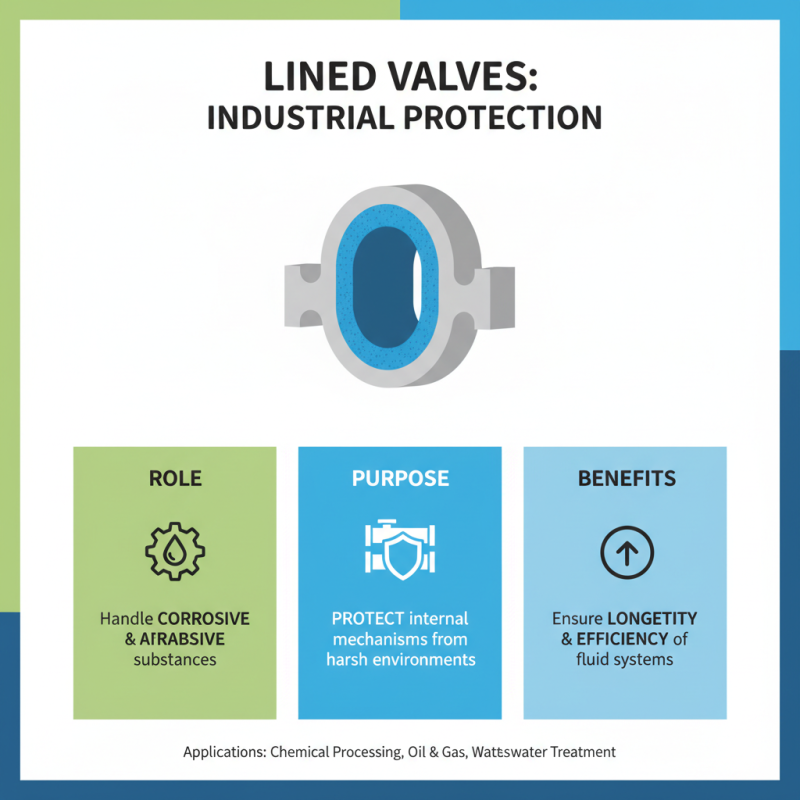

Understanding the Purpose of Lined Valves in Industrial Settings

Lined valves play a crucial role in various industrial applications by providing a reliable solution for handling corrosive substances and abrasive materials. The primary purpose of these valves is to protect the internal mechanisms from the harsh environments often encountered in industries such as chemical processing, oil and gas, and wastewater treatment. By utilizing lining materials that are resistant to chemicals and wear, lined valves ensure the longevity and efficiency of the fluid control systems.

When selecting lined valves, it is essential to consider the specific requirements of the application. Factors such as the type of fluid being transported, temperature, and pressure conditions must be evaluated to determine the most suitable lining material. In addition, the valve's design and size should align with the system's operational specifications to guarantee optimal performance. A thorough understanding of these elements will help industries minimize downtime and maintenance costs while enhancing safety and reliability in their operations.

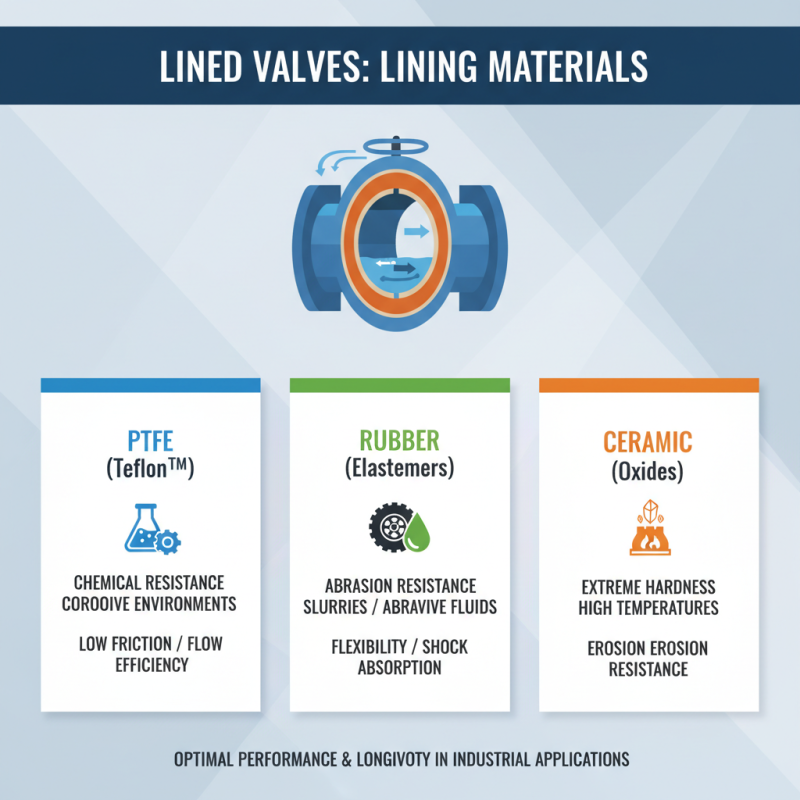

Evaluating Different Types of Lining Materials for Valves

When selecting the right lined valves for industrial applications, evaluating the different types of lining materials is crucial to ensure optimal performance and longevity. Common lining materials include PTFE, rubber, and ceramic, each offering distinct advantages based on the specific requirements of the application. PTFE, known for its excellent chemical resistance, is ideal for corrosive environments. It ensures that the valve maintains integrity under harsh conditions while providing a low-friction surface that enhances flow efficiency.

Rubber linings, often used in applications involving slurries or abrasive materials, provide an effective barrier against wear and tear. The flexibility of rubber can accommodate shifts in temperature and pressure, making these valves suitable for dynamic conditions. On the other hand, ceramic linings excel in high-temperature applications and possess superior hardness, making them ideal for abrasive substances. Therefore, understanding the unique properties of each lining material is essential for selecting the most appropriate lined valve that meets the specific operational demands of your industrial processes.

Key Factors to Consider When Selecting Lined Valves

When selecting lined valves for industrial applications, several key factors must be taken into account to ensure optimal performance and longevity. The chemical compatibility is paramount; choosing materials that can effectively withstand the corrosive nature of the fluids being transported is essential. According to a report by the American Society of Mechanical Engineers (ASME), almost 30% of valve failures stem from improper material selection, highlighting the necessity of assessing the properties of both the lining and the environment.

Another critical aspect to consider is temperature and pressure ratings. Lined valves are utilized in various settings where extreme conditions can occur. Data from the Valve Manufacturers Association of America indicates that 25% of industrial processes operate beyond standard temperature and pressure ranges, which can significantly impact valve performance. Ensuring that the selected valve can handle these parameters will mitigate risks and enhance operational efficiency.

Tips: Always consult the technical specifications and testing standards relevant to the specific lining materials and valve designs. Additionally, consider engaging with industry experts or utilizing simulation software to predict performance outcomes in your specific application. Conducting thorough assessments on maintenance requirements can also lead to cost savings in the long run.

Assessing the Operating Conditions for Valve Selection

When selecting lined valves for industrial applications, a critical step is to thoroughly assess the operating conditions that the valves will encounter. Factors such as temperature extremes, pressure levels, and the chemical nature of the fluids play a crucial role in determining the most suitable valve type. For instance, according to a report by the International Society of Automation, nearly 40% of valve failures in industrial settings are attributed to inappropriate material selection based on operational parameters. Therefore, it is essential to analyze the fluid characteristics and environmental conditions to select lined valves that can withstand abrasion, corrosion, and thermal stress.

Additionally, understanding the flow characteristics and the valve's required performance under specific operating conditions is imperative. A study published in the Journal of Pipeline Engineering emphasizes that valves that are not appropriately matched to their operating conditions can lead to efficiency losses of up to 15%. This inefficiency can result from issues such as flow turbulence, which can be exacerbated by the valve design and lining materials. Consequently, it is vital to gather and analyze relevant data regarding process dynamics, including flow rate variations and potential pressure surges, to ensure that the chosen lined valves not only meet operational demands but also contribute to enhanced system reliability and longevity.

Maintenance and Performance Considerations for Lined Valves

When selecting lined valves for industrial applications, maintenance and performance considerations are paramount. Lined valves are essential in environments where aggressive chemicals and corrosive substances are prevalent, as they provide significant protection against wear and degradation. According to the Chemical Engineering Plant Cost Index (CEPCI), the cost of downtime for maintenance can reach up to 20% of total operational costs in certain industries. This statistic emphasizes the importance of choosing high-quality lined valves that not only withstand harsh conditions but also minimize maintenance requirements.

Regular inspection and maintenance of lined valves are crucial to ensure optimal performance and longevity. A report from the American Society of Mechanical Engineers (ASME) indicates that nearly 30% of valve failures are attributable to improper maintenance practices. Implementing a robust maintenance schedule can significantly reduce the incidence of valve failures, thereby enhancing system reliability and efficiency. Moreover, industry best practices recommend using advanced materials, such as fluoropolymers, to line valves, which can extend their lifespan and improve their resistance to chemical attack.

Additionally, the integration of technology in monitoring valve performance is becoming increasingly important. The use of smart sensors can provide real-time data on valve condition, allowing for proactive maintenance. A study by the Valve Manufacturers Association (VMA) revealed that facilities employing condition-based maintenance strategies for their valves experienced a 40% reduction in unexpected failures. By understanding these maintenance and performance considerations, industries can make informed decisions when selecting lined valves, ultimately enhancing operational efficiency and reducing costs.

Related Posts

-

5 Essential Tips for Choosing the Right Lined Valves for Your Industrial Needs

-

Mastering BFV Valves: A Comprehensive Tutorial on Selection, Sizing, and Optimization Techniques

-

Mastering Ball Valve Selection: A Comprehensive Tutorial for Optimal Flow Control in Industrial Applications

-

Understanding the Importance of Air Valve Types in Industrial Applications

-

Common Issues Faced by Global Buyers When Sourcing Gas Valves: A Comprehensive Guide

-

Understanding the Benefits of Ball Check Valves in Industrial Applications: A Comprehensive Guide