Top 10 Tips for Choosing the Right PTFE Valve for Your Applications

Choosing the right PTFE valve for your specific applications can significantly impact operational efficiency and safety in varied industries, including pharmaceuticals, chemicals, and food processing. According to a report by the International Valve Association, the global valve market is projected to reach approximately $80 billion by 2025, with PTFE valves playing a crucial role in this growth due to their exceptional resistance to chemicals and high-temperature applications. This underscores the necessity for industries to carefully consider the selection of PTFE valves as they seek to enhance process reliability and performance.

As noted by industry expert Dr. Richard Melton, "Selecting the appropriate PTFE valve is not just about compatibility with the medium; it’s about understanding the entire system’s requirements to ensure optimal functionality and longevity." Dr. Melton's insights reflect a growing recognition within the sector that the success of industrial operations often hinges on the nuances of valve selection. In this article, we will explore the top ten tips for selecting the right PTFE valve, enabling professionals to make informed decisions that align with their operational needs and industry standards.

Understanding PTFE Valves: Key Characteristics and Benefits

PTFE valves, known for their exceptional chemical resistance and durability, are essential in various industrial applications. These valves are primarily made from polytetrafluoroethylene (PTFE), a material that offers a unique combination of low friction, non-reactivity, and high thermal stability, making them ideal for handling aggressive chemicals. According to a report from the Global Valve Market analysis, the demand for PTFE valves in the chemical processing sector is projected to grow at a CAGR of 6.4% from 2021 to 2026, reflecting the increasing need for reliable and long-lasting solutions in hazardous environments.

One of the key characteristics of PTFE valves is their ability to operate at elevated temperatures and pressures without compromising performance. Standard PTFE valves can typically withstand temperatures up to 300°F (149°C) and pressures ranging from full vacuum to 150 psi. This operational versatility, combined with their resistance to corrosion, positions PTFE valves as a preferred option in industries such as pharmaceuticals, food processing, and wastewater management. Furthermore, the low friction properties of PTFE not only enhance the valve's operational lifespan but also reduce maintenance requirements, leading to significant cost savings over time. Thus, understanding these characteristics is crucial for selecting the right PTFE valve tailored to specific application requirements.

Assessing Compatibility: Identifying Your Application's Requirements

When selecting a PTFE valve for your applications, understanding compatibility is crucial. The first step is to clearly identify the operational parameters of your application. This includes considering factors such as temperature, pressure, and the nature of the media being handled. PTFE valves are known for their exceptional chemical resistance and can handle a wide variety of substances, but it’s important to match the valve specifications with the requirements of your application to ensure optimal performance.

Additionally, assessing the valve’s design and construction is key in ensuring compatibility. Different PTFE valves are designed for various operational environments, and features such as the valve’s sealing mechanism and body material can significantly impact their performance in specific applications. Always take into account the connection types and installation space available, as these can limit your choices. By aligning the valve’s features with your application’s requirements, you can ensure reliable operation and longevity of your equipment.

Evaluating Valve Design: Types and Configurations of PTFE Valves

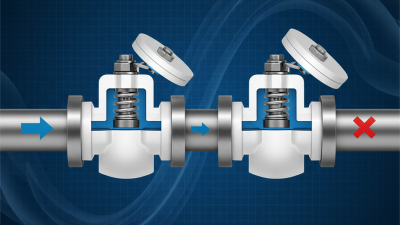

When evaluating the design of PTFE valves, it's essential to consider the various types and configurations available to meet specific application needs. PTFE, or polytetrafluoroethylene, is known for its excellent chemical resistance and high-temperature stability, making it an ideal choice for many industrial settings. Among the different types of PTFE valves, ball valves, diaphragm valves, and butterfly valves are popular. Each type offers unique operational benefits: ball valves provide quick shut-off capabilities, diaphragm valves offer precise flow control, and butterfly valves are ideal for large flow rates with minimal pressure drop.

Moreover, the configuration of the valve significantly impacts its performance. Valves can be designed with full-port or reduced-port options, influencing the flow capacity and pressure drop across the valve. Additionally, the installation configurations—such as inline or angle—can affect how the valve integrates with existing systems. Understanding these design elements allows for a more informed selection process, ensuring that the chosen PTFE valve aligns with the intended application while maximizing efficiency and reliability in operation.

Top 10 PTFE Valve Types and Their Applications

Material Composition: Importance of High-Quality PTFE Standards

When selecting a PTFE valve for specific applications, understanding the material composition is crucial. PTFE, or Polytetrafluoroethylene, is renowned for its chemical resistance, thermal stability, and low friction properties. However, not all PTFE materials are created equal. High-quality PTFE standards, such as those outlined by organizations like ASTM and ISO, ensure that the PTFE used in manufacturing valves meets stringent criteria for purity, consistency, and performance. For instance, reports from the International Journal of Material Science highlight that PTFE with higher molecular weight exhibits improved mechanical properties and longevity, making it essential for applications in corrosive environments.

The importance of high-quality PTFE extends beyond performance; it directly impacts the safety and reliability of systems that utilize these valves. Research indicates that subpar PTFE can lead to premature wear, leakage, and even catastrophic failures in high-pressure applications. According to a study published by the Chemical Engineering Research Association, valves constructed from high-standard PTFE can withstand temperatures up to 260°C and pressures exceeding 25 bar without significant degradation. This makes them suitable for a wide range of industries, from pharmaceuticals to petrochemicals, where material integrity is paramount.

Choosing PTFE valves that adhere to high-quality standards not only enhances operational efficiency but also mitigates risks associated with valve failure.

Cost vs. Quality: Balancing Budget with Performance Needs in Selection

When selecting the right PTFE valve for specific applications, striking a balance between cost and quality is crucial. According to a report from the Chemical Engineering Journal, the performance of valves made from polytetrafluoroethylene (PTFE) can significantly impact operational efficiency. High-quality PTFE valves may have a higher initial cost, but their durability and resistance to corrosive chemicals can ultimately lead to lower maintenance expenses and extended service life. In fact, a study by the Valve Manufacturers Association indicates that investing in superior materials can save up to 25% in maintenance costs over a valve's lifecycle.

Moreover, it is essential to consider the specific demands of your application. Research conducted by the American Society of Mechanical Engineers highlights that using valves that meet industry standards enhances overall system performance. While cheaper alternatives may initially seem attractive, they often compromise on essential features such as pressure handling capacity and temperature resistance, which are critical in high-stakes environments. Choosing quality PTFE valves not only assures compliance with safety regulations but can also deliver better performance, ultimately contributing to a more sustainable operational budget. Therefore, carefully weighing the cost against the performance needs can lead to better long-term outcomes and reliability in industrial applications.

Related Posts

-

Ultimate Checklist for Choosing the Right PTFE Valve for Your Industrial Needs

-

What is a PTFE Lined Check Valve and How Does it Work in Fluid Systems

-

Mastering BFV Valves: A Comprehensive Tutorial on Selection, Sizing, and Optimization Techniques

-

How to Choose the Right Lined Valves for Your Industrial Applications

-

Understanding the Importance of Pneumatic Ball Valves in Modern Industrial Applications

-

Understanding the Role of Check Valves in Fluid Control Systems for Enhanced Efficiency