How to Choose the Right Steam Control Valve for Your Application

Choosing the right steam control valve for your application is a critical decision that can significantly impact system performance, efficiency, and safety. Steam control valves are essential components in various industrial processes, regulating steam flow and maintaining the desired pressure and temperature levels. The right selection ensures optimum operation while minimizing maintenance costs and energy consumption.

When evaluating the appropriate steam control valve, it is important to consider various factors such as the specific requirements of your application, including pressure ratings, flow characteristics, and the nature of the steam system. Understanding these parameters helps to identify the most suitable valve type and design, ensuring that it meets the demands of your operational environment. Additionally, proper knowledge of materials and sealing options can prevent common issues like leakage and corrosion, further enhancing the valve’s reliability.

In this guide, we will explore the key considerations and best practices for selecting steam control valves, equipping you with the knowledge necessary to make informed decisions. By doing so, you can optimize your steam system's efficiency and longevity, ultimately contributing to the overall success of your operations.

Understanding the Role of Steam Control Valves in Industrial Applications

Steam control valves play a critical role in managing the flow and pressure of steam within various industrial applications, making them essential for optimizing efficiency and safety in operations. In many manufacturing sectors, including food processing, pharmaceuticals, and power generation, the precise control of steam conditions can significantly impact product quality and system reliability. According to the International Society of Automation (ISA), improper steam management can lead to energy losses of up to 30%, making the selection of an appropriate steam control valve even more vital.

In selecting a steam control valve, factors such as valve size, type, and materials must be carefully considered. Demand for precise control capabilities is surging, driven by advancements in automation and process control technologies. A report by Global Market Insights estimates that the global steam control valve market is projected to exceed USD 5 billion by 2025, highlighting the increasing importance of these components in industrial processes. Furthermore, the incorporation of smart technologies, including sensors and monitoring systems, can enhance the effectiveness of steam control valves, allowing for real-time adjustments and maintenance alerts that further reduce inefficiencies and downtime.

Understanding the specific steam requirements of an application—such as temperature, pressure, and flow rate—is crucial for making informed decisions. A well-chosen valve not only ensures optimal performance but also contributes to longevity and lower operational costs. The ability to adapt to varying conditions while maintaining accurate control is a hallmark of high-quality steam control valves, underscoring their significance in contemporary industrial practices.

Steam Control Valve Selection Insights

This chart represents the comparison of different steam control valve types and their effectiveness based on applications in the industrial sector. The effectiveness is measured on a scale of 1 to 10, where 10 indicates the highest level of effectiveness for specific applications.

Key Factors to Consider When Selecting a Steam Control Valve

When selecting a steam control valve for your application, several key factors should be considered to ensure optimal performance and reliability. First, you need to assess the operational parameters such as temperature and pressure. Different valves are designed to handle various steam conditions, and choosing one that meets the specific demands of your system is crucial for maintaining efficiency and safety. Additionally, understanding the application's flow requirements can guide you in selecting a valve that provides the adequate capacity and response time.

Tips: Always consult technical specifications and data sheets to compare the characteristics of different valves. Additionally, consider the installation environment, as factors like space constraints and accessibility can influence your choice significantly.

Another vital aspect to consider is the valve’s materials of construction. The materials should be suitable for steam applications and resistant to corrosion and wear. For instance, stainless steel is often a preferred choice due to its durability and ability to maintain integrity under fluctuating temperatures. Moreover, don’t overlook the actuator type; pneumatic, electric, or manual actuators can drastically affect the control precision and speed of the valve.

Tips: Evaluate the total cost of ownership, including maintenance and replacement needs, when choosing a valve. A higher upfront cost can sometimes lead to lower operational costs over time if the valve is more durable and efficient.

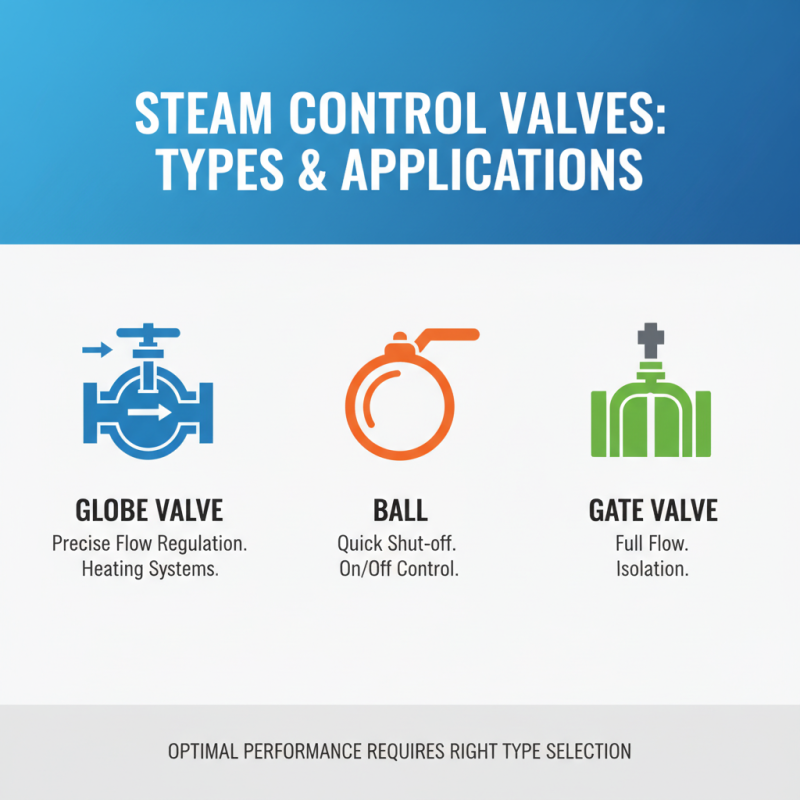

Types of Steam Control Valves and Their Specific Applications

When selecting a steam control valve, understanding the different types and their specific applications is critical for optimal performance. Generally, the most common types of steam control valves include globe valves, ball valves, and gate valves. Each serves a distinct purpose depending on the operational needs of the system. Globe valves, with their excellent throttling capabilities, are often used in applications requiring precise flow regulation. Their design allows for significant control over the flow rate, making them suitable for processes like steam distribution in heating applications.

Ball valves, known for their quick-switching capabilities, are ideal for applications that involve frequent cycling. They provide a tight seal and are best suited for on/off control rather than throttling. In contrast, gate valves are typically used in applications where the flow needs to be fully turned on or off, as they allow for minimal pressure drop when fully opened. By understanding these various types of steam control valves, engineers can select the most appropriate option based on the specific requirements of temperature, pressure, and flow regulation in their systems.

Installation and Maintenance Best Practices for Steam Control Valves

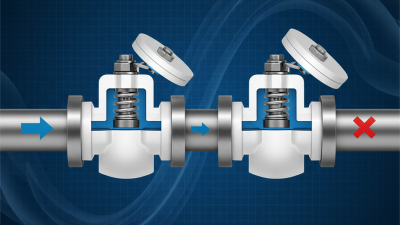

When it comes to the installation and maintenance of steam control valves, adhering to

best practices is essential to ensure

optimal performance and longevity. One critical aspect of installation is ensuring that the valve is positioned

correctly concerning the flow direction. Incorrect installation can result in significant operational issues,

including inefficient steam flow and premature wear of valve components. It is also vital to inspect the piping

and connections for any leaks before putting the system into operation.

Tips: Always consult the manufacturer’s specifications for proper installation procedures

and torque requirements on flanged connections. Using the right tools and following the recommended tightening

sequence can help prevent damage to valve components.

Regular maintenance is equally important in maximizing the lifespan of steam control valves. Schedule periodic

inspections to check for signs of wear or damage, such as leaks, corrosion, or unusual noises. Additionally,

keeping the valve clean and lubricated helps maintain

its functionality. Checking the actuator and control mechanisms ensures that they respond accurately to system

demands, preventing potential failures during operation.

Tips: Implement a monitoring system to track the

performance of your steam control valves. This proactive approach allows for early detection of issues,

ensuring timely maintenance and reducing the risk of unscheduled downtimes.

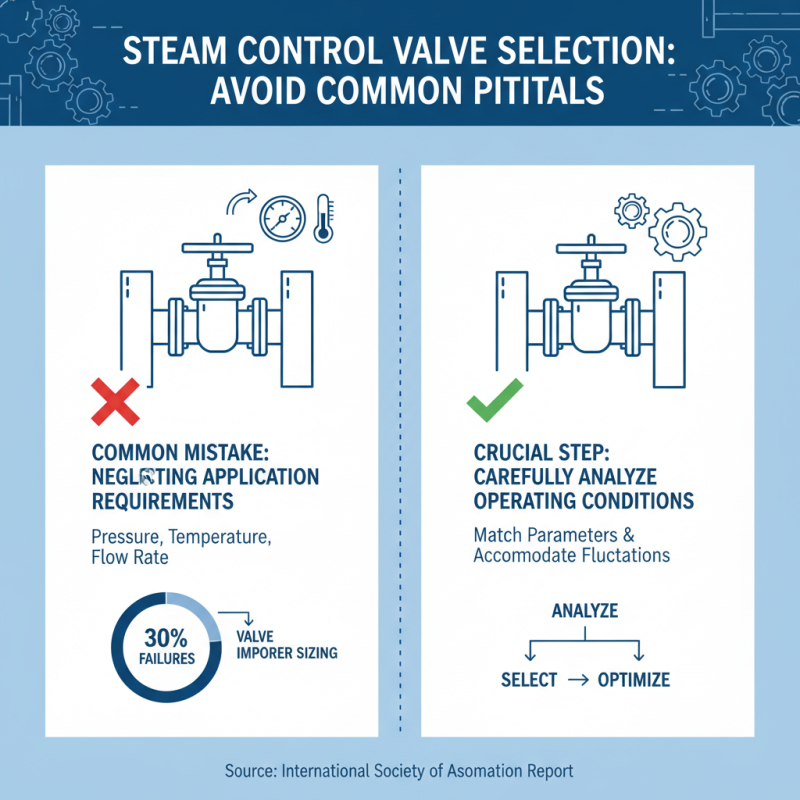

Common Mistakes to Avoid When Choosing a Steam Control Valve

When selecting a steam control valve, avoiding common pitfalls is crucial for ensuring optimal performance and longevity of your system. One frequent mistake is neglecting to consider the specific application requirements, such as pressure, temperature, and flow rate. According to a recent industry report by the International Society of Automation, approximately 30% of valve failures can be traced back to improper sizing and selection. Therefore, it's essential to carefully analyze the operating conditions and select a valve that not only fits these parameters but also accommodates potential fluctuations in demand.

Another common error is overlooking the impact of valve materials on performance. For instance, using the wrong materials can lead to corrosive degradation, especially in high-pressure or high-temperature steam environments. A study conducted by the Valve Manufacturers Association indicated that material selection can influence the lifespan of a valve by up to 50%. Choosing valves made from appropriate materials, such as stainless steel or specialized alloys for corrosive applications, is vital to ensure durability and efficiency. These considerations can prevent costly maintenance issues and operational downtimes, further underscoring the importance of meticulous valve selection processes in industrial applications.

Related Posts

-

Understanding the Benefits of Ball Check Valves in Industrial Applications: A Comprehensive Guide

-

Unlocking Efficiency: How Ball Valve Actuators Revolutionize Industrial Automation Systems

-

Understanding the Mechanisms and Benefits of Ball Check Valves in Modern Applications

-

What is a PTFE Lined Check Valve and How Does it Work in Fluid Systems

-

Understanding Industry Standards for the Best Actuator Valve and How to Choose the Right One

-

Understanding Lockable Ball Valves: Key Features and Industry Insights Shaping Fluid Control Systems