What is a Pressure Valve and How Does it Work?

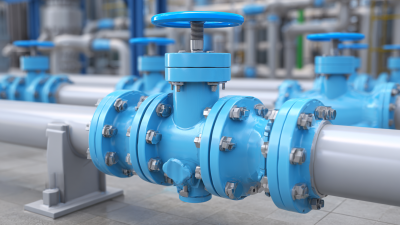

A pressure valve is a critical component in various industrial applications. It regulates the flow of liquids or gases, ensuring systems operate safely. According to John Smith, an expert in fluid dynamics, "A pressure valve is essential for the integrity of pressurized systems." His words highlight the importance of these devices.

In essence, pressure valves help prevent equipment failure. They do this by controlling pressure levels. For example, in boilers, pressure valves keep steam pressure within safe limits. Without them, accidents could occur.

However, pressure valves are not flawless. They can malfunction or become blocked, leading to potential hazards. Regular maintenance is necessary to ensure reliability. The industry must reflect on these challenges to improve safety standards.

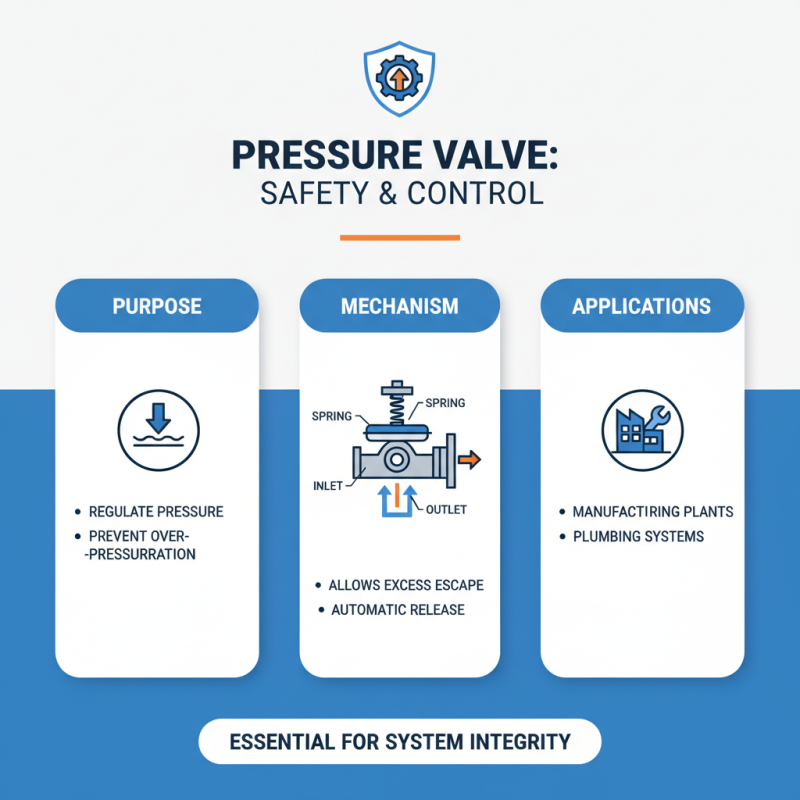

Definition of a Pressure Valve and Its Purpose

A pressure valve is an essential component in many systems. Its primary purpose is to control pressure levels. It allows excess pressure to escape, ensuring safety and functionality. This mechanism can be found in different industries, including manufacturing and plumbing.

When pressure builds up beyond a set limit, the valve opens automatically. This action releases excess pressure, preventing damage to the system. For instance, in steam boilers, it helps maintain optimal pressure levels. The design varies; some valves are spring-loaded, while others are diaphragm-based. It's fascinating how something so small can have a significant impact on safety.

However, not all pressure valves work flawlessly. Sometimes, they can stick or malfunction, leading to pressure build-up. Regular maintenance is crucial to ensure they function as intended. Ignoring small issues could result in bigger problems. Ensuring the right type of pressure valve is selected for a specific application is equally important.

Types of Pressure Valves and Their Applications

Pressure valves come in various types, each with unique applications. One common type is the relief valve. This valve protects systems from excessive pressure. It opens to release pressure, ensuring safety. Often used in boilers and pumps, the relief valve prevents explosions.

Another type is the control valve. This valve regulates pressure and flow. It adjusts based on the system's requirements. These valves are crucial in HVAC systems. They maintain comfort by ensuring proper airflow and temperature.

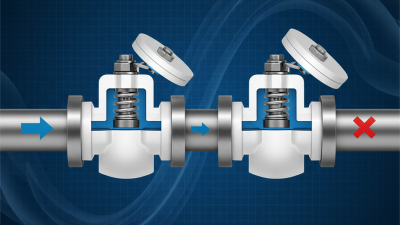

Then there are check valves. They allow fluid to flow in one direction only. This prevents backflow, which can damage equipment. They're often found in pipelines and drainage systems. Understanding these types helps in selecting the right valve for specific needs. Each type has its strengths and weaknesses. Knowing when to use each valve can be challenging.

How Pressure Valves Function Mechanically

Pressure valves are crucial in various systems. They control the flow and maintain stability. Their mechanism is simple yet effective. A pressure valve opens or closes in response to pressure changes, allowing or restricting fluid flow. This action prevents systems from over-pressurizing.

Understanding these mechanics can lead to improvements. Many users overlook small adjustments, which can have significant effects. For example, tuning the spring tension might optimize performance. Little changes often yield better results. Therefore, always reflect on how your systems function. Explore ways to enhance the longevity of your pressure valve.

Factors Influencing Pressure Valve Performance

Pressure valves play a critical role in maintaining system integrity. Their performance hinges on multiple factors. One major influence is the material used in valve construction. High-quality alloys can withstand higher pressures, enhancing durability. Research indicates that valves made from stainless steel can handle up to 20% more pressure than those made from standard brass.

Another critical factor is the valve design. A well-engineered valve shape improves fluid dynamics and reduces turbulence. Studies show that optimized flow paths can decrease pressure drops by 15% or more. However, not all designs account for varying operational conditions. Some valves struggle under extreme temperatures, leading to failures. Industry reports reveal that improper design contributes to 30% of valve malfunctions.

Lastly, installation plays a vital role in valve efficiency. Incorrect alignment can lead to excessive wear and tear. A survey found that nearly 25% of issues stem from poor installation practices. Regular maintenance and checks also affect performance longevity. Ignoring these factors can result in costly downtimes. Each operational aspect requires careful consideration for optimal function.

Pressure Valve Performance Factors

This bar chart illustrates the performance impact of various factors on pressure valves. Each factor, such as temperature, fluid viscosity, fluid density, flow rate, and pressure setting, influences the overall efficiency and operation of a pressure valve. The values are scaled from 0 to 100, representing their relative impact level.

Maintenance and Troubleshooting of Pressure Valves

Pressure valves are essential in many systems. They help control and maintain pressure effectively. Regular maintenance is key to their proper functioning. Neglecting this can lead to costly repairs and downtime.

One common issue is leaks. Check the valve seals regularly. Ensure there are no cracks or wear. Tighten connections if necessary. Make sure the valve operates smoothly. A jammed valve can cause pressure buildup. Address this promptly to avoid failures.

Tips: Regularly inspect the pressure settings. Adjust them as needed. Always keep an eye out for unusual noises. This can indicate underlying problems. Remember, even minor issues can escalate quickly. If your valve exhibits strange behavior, it’s best to troubleshoot immediately. Don’t wait for a complete breakdown.

Tools to help assess the valve's state include pressure gauges. Use them for accurate readings.

Related Posts

-

Top 10 Tips for Choosing the Right PTFE Valve for Your Applications

-

10 Essential Tips for Choosing the Right Gas Valve for Your Needs

-

What is a Check Valve and How Does It Work in Fluid Systems

-

How to Choose the Right Industrial Valves for Your Manufacturing Needs

-

Ultimate Guide to Selecting the Right Industrial Valves for Your Applications

-

What is a PTFE Lined Check Valve and How Does it Work in Fluid Systems