What is a PTFE Lined Check Valve and How Does it Work in Fluid Systems

In fluid systems, maintaining unidirectional flow is essential for optimal performance and safety. One key component in achieving this is the PTFE lined check valve. This innovative valve design integrates a Teflon (PTFE) lining, providing exceptional resistance to corrosion and minimizing friction, which is crucial in handling various types of fluids. Understanding the function and importance of a PTFE lined check valve is vital for engineers and operators working in industries such as chemical processing, pharmaceuticals, and wastewater management.

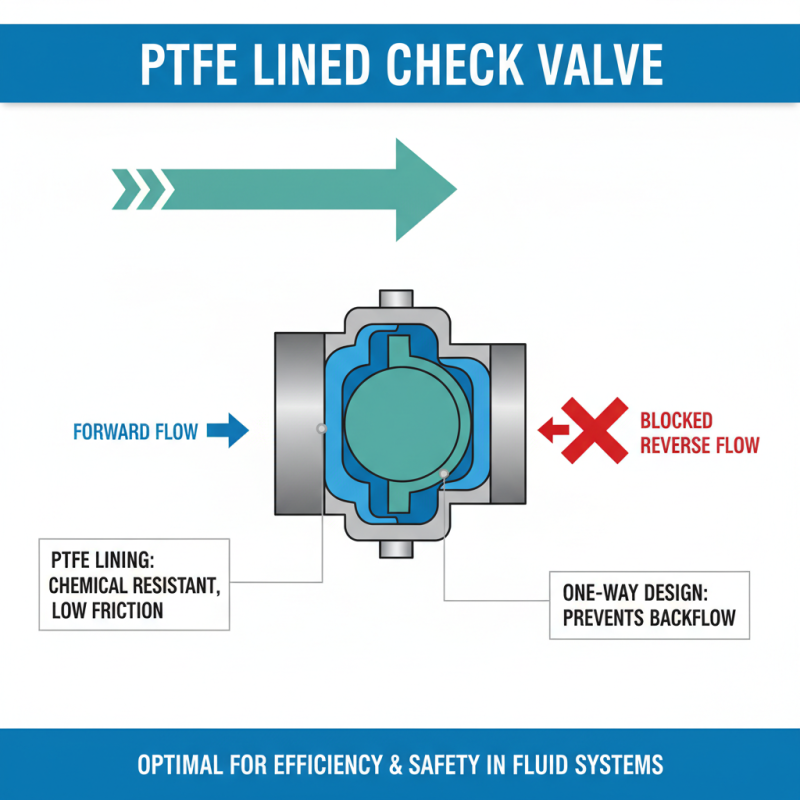

The PTFE lined check valve operates by allowing fluid to flow through in a single direction while automatically preventing backflow. This capability is especially significant in systems where cross-contamination must be avoided and where pressure fluctuations could threaten system integrity. The unique properties of the PTFE lining ensure that the valve functions efficiently in harsh environments, making it a reliable choice for fluid control applications. By exploring the construction, operation, and benefits of the PTFE lined check valve, this discussion aims to highlight its role in enhancing the reliability and safety of fluid systems.

Definition and Purpose of PTFE Lined Check Valves in Fluid Systems

PTFE lined check valves play a crucial role in fluid systems, serving the essential purpose of preventing backflow while ensuring the efficient flow of fluids. Constructed with a lining of polytetrafluoroethylene (PTFE), these valves are particularly well-suited for handling corrosive and reactive substances. The PTFE lining offers superior chemical resistance, enabling the valve to maintain its integrity and functionality in harsh environments. This feature makes PTFE lined check valves an ideal choice for industries such as chemical processing, pharmaceuticals, and food production, where safeguarding the purity of the fluid is paramount.

The design of PTFE lined check valves allows for smooth, unidirectional flow while automatically closing when fluid attempts to flow back. This automatic closure minimizes the risk of contamination and protects downstream equipment from potential damage caused by backflow. The valve operates through a simple mechanism, typically involving a disc or ball that moves in response to fluid pressure. When the fluid flows in the intended direction, the pressure lifts the disc or ball, allowing flow. Conversely, if backflow occurs, the disc or ball is seated against the valve body, effectively sealing the system and preventing reverse flow. This reliability and simplicity of operation reinforce the essential role of PTFE lined check valves in maintaining the safety and efficiency of fluid transport systems.

Key Materials Used in PTFE Lined Check Valve Construction

PTFE lined check valves are essential components in various fluid systems, particularly due to their unique lining material, polytetrafluoroethylene (PTFE). The primary advantage of PTFE is its remarkable chemical resistance, which makes it suitable for handling aggressive fluids and harsh environments. A significant characteristic of PTFE is its low friction coefficient, which enhances the performance and efficiency of check valves by allowing smoother fluid flow and reducing wear over time. Industry reports indicate that PTFE's excellent thermal stability can withstand temperatures ranging from -200 °C to +260 °C, making it a versatile choice in a wide range of applications.

The construction of a PTFE lined check valve typically consists of a solid metal body, often made from stainless steel or carbon steel, and a thick PTFE lining that coats the interior surface. This effective combination protects the valve body from corrosive effects while ensuring the internal components remain intact and function correctly. According to recent research from the Flow Control Industry, the demand for PTFE lined products has surged by 15% annually, driven by the growth of the chemical processing industry and increased focus on system integrity and reliability. Furthermore, studies demonstrate that PTFE lined valves exhibit significantly longer service life than their non-lined counterparts, reducing maintenance costs and downtime in fluid handling systems.

Mechanism of Action: How PTFE Lined Check Valves Function

PTFE lined check valves are designed to prevent backflow in fluid systems, and their mechanism of action is crucial for maintaining the efficiency and safety of various applications. These valves utilize a one-way design that allows fluid to flow in a designated direction while effectively blocking reverse flow. The inner lining of PTFE (polytetrafluoroethylene), known for its excellent chemical resistance and low friction properties, plays a vital role in ensuring smooth operation, even in extreme conditions.

When fluid pressure is applied in the forward direction, the valve opens, allowing fluid to pass through the lining. As the flow stops or attempts to reverse, the valve automatically closes due to the weight of the valve disc or the pressure difference created by the fluid. This swift closure minimizes the risk of cavitation, slamming, or pressure surges, which can be detrimental to the system. The PTFE lining also prevents corrosion and wear, ensuring a longer lifespan and reliability, making these check valves particularly useful in harsh environments where other materials may fail.

Applications of PTFE Lined Check Valves in Various Industries

PTFE lined check valves are utilized across various industries due to their exceptional resistance to corrosion and ability to handle aggressive fluids. In the chemical processing sector, for example, these valves are crucial for ensuring the integrity of fluid systems transporting acids, bases, and solvents. The PTFE lining provides a protective barrier, reducing the risk of leaks and environmental contamination. This reliability is essential in maintaining safety standards and minimizing downtime in production processes.

Another significant application of PTFE lined check valves can be found in the pharmaceutical industry. Here, the purity and cleanliness of fluids are paramount. The non-stick properties of PTFE help to prevent residue buildup, ensuring that products are free from contamination. These valves are also easy to clean, which helps to meet stringent regulatory requirements for hygiene and product quality. By incorporating PTFE lined check valves into fluid systems, manufacturers can enhance operational efficiency while maintaining the necessary compliance standards.

Advantages of Using PTFE Lined Check Valves Over Traditional Options

PTFE lined check valves offer several advantages over traditional valve options that make them particularly suitable for a range of fluid systems. One of the primary benefits is their superior chemical resistance. PTFE, or polytetrafluoroethylene, is known for its ability to withstand aggressive chemicals and high temperatures, making it ideal for industries such as pharmaceuticals, chemicals, and food processing. Unlike traditional metal or rubber-lined valves, which can corrode, degrade, or lose integrity when exposed to harsh substances, PTFE lined valves maintain their performance and reliability over time.

Another significant advantage of PTFE lined check valves is their low friction characteristics, which enhance flow efficiency. The smooth surface of PTFE reduces turbulence and resistance, allowing fluids to flow more freely through the system. This not only improves the overall efficiency of the fluid transfer but also extends the lifespan of the valve itself, as there is less wear and tear due to friction. Additionally, PTFE's non-stick properties prevent the accumulation of scales or deposits, which can be a common issue with conventional check valves. As a result, these valves require less maintenance and offer long-term cost savings for industries relying on seamless operation in demanding fluid systems.

What is a PTFE Lined Check Valve and How Does it Work in Fluid Systems - Advantages of Using PTFE Lined Check Valves Over Traditional Options

| Feature | PTFE Lined Check Valve | Traditional Check Valve |

|---|---|---|

| Material | PTFE Lining | Metal or Plastic |

| Temperature Resistance | -200°C to 260°C | -40°C to 200°C |

| Chemical Resistance | Excellent | Moderate |

| Weight | Lightweight | Heavier |

| Maintenance | Low Maintenance | Moderate Maintenance |

| Application | Corrosive Fluids | Non-Corrosive Fluids |

| Cost | Higher Initial Cost | Lower Initial Cost |

| Life Span | Longer | Shorter |

Related Posts

-

Unmatched Excellence in PTFE Lined Check Valves: Crafted in China, Delivered Worldwide

-

Understanding the Benefits and Applications of Lockable Ball Valves in Industrial Settings

-

Understanding Lockable Ball Valves: Key Features and Industry Insights Shaping Fluid Control Systems

-

How to Optimize Your Pipeline Efficiency with Ball Check Valves: Best Practices and Insights

-

Top 10 Ball Valve Actuators for Efficient Industrial Applications

-

Understanding the Benefits of Ball Check Valves in Industrial Applications: A Comprehensive Guide