Top 10 Ball Valve Actuators for Efficient Industrial Applications

In the realm of industrial automation, the significance of an efficient ball valve actuator cannot be overstated. These devices play a crucial role in ensuring that processes run smoothly and safely, particularly in sectors such as oil and gas, water treatment, and chemical manufacturing. According to industry expert Dr. Emily Thompson, a prominent figure in valve technologies, "The right ball valve actuator can dramatically improve operational efficiency and reduce maintenance costs." Her insights highlight the importance of selecting the appropriate actuator to meet the specific demands of different applications.

With a rising emphasis on energy efficiency and sustainability, understanding the various types of ball valve actuators available in the market becomes paramount. This comprehensive overview will explore the top ten ball valve actuators designed for industrial settings, emphasizing their performance characteristics, advantages, and best-use scenarios. By examining these leading options, professionals can make informed decisions that enhance process control and operational effectiveness, ultimately contributing to a more sustainable industrial future.

Overview of Ball Valve Actuators in Industrial Applications

Ball valve actuators play a crucial role in optimizing industrial processes by enhancing control over fluid flow in various applications. These actuators can be powered electrically, pneumatically, or hydraulically, each offering distinct advantages that cater to specific operational needs. According to a report by MarketsandMarkets, the global ball valve actuator market is projected to grow from $1.5 billion in 2020 to $2.1 billion by 2025, reflecting a compound annual growth rate (CAGR) of 6.4%. This growth underscores the increasing reliance on automation and the demand for efficient process control in industries such as oil and gas, water treatment, and chemical manufacturing.

In practice, ball valve actuators contribute to improved efficiency by enabling quick operation and precise modulation of flow rates. The implementation of modern actuators can lead to significant energy savings and reduced operational downtime. A study by Research and Markets highlights that the integration of smart technologies with ball valve actuators can enhance performance monitoring and predictive maintenance, thus furthering operational reliability. Moreover, the ability to integrate these actuators with existing industrial control systems showcases their versatility and importance in modern industrial environments.

Types of Ball Valve Actuators and Their Mechanisms

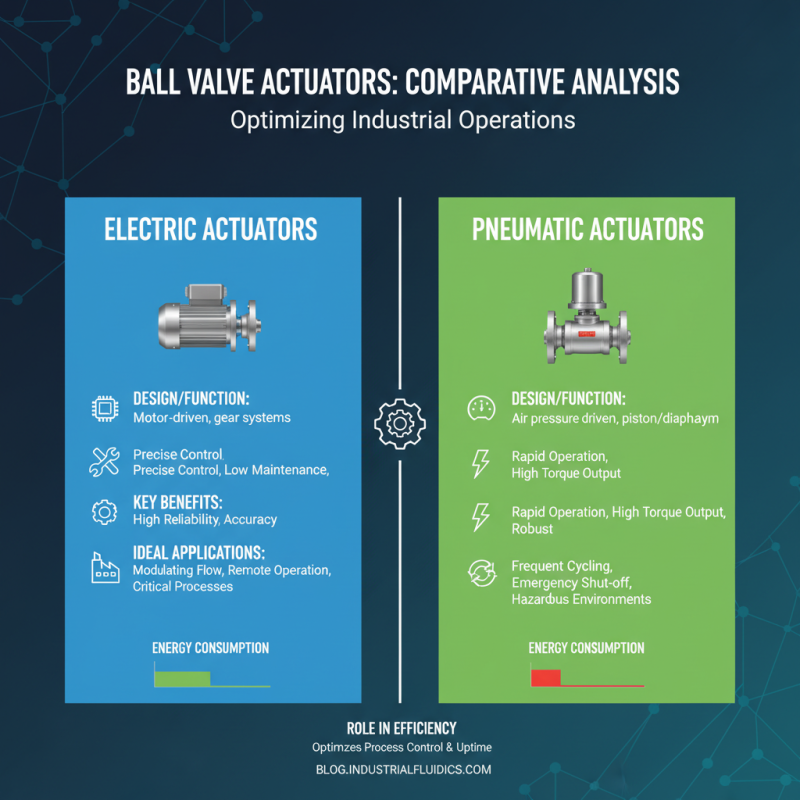

Ball valve actuators play a crucial role in the automation of industrial processes, providing efficient control of fluid flow through pipes and valves. These actuators operate through various mechanisms, each suited to different applications and conditions. The most common types of ball valve actuators include electric, pneumatic, and hydraulic actuators.

Electric actuators utilize electric motors to provide precise control and are ideal for applications requiring frequent adjustments. Pneumatic actuators, on the other hand, use compressed air to drive the valve, making them suitable for rapid operations in environments where speed is essential. Hydraulic actuators rely on pressurized fluid to operate valves, offering high force and reliability, particularly in heavy-duty applications.

When selecting a ball valve actuator, it’s important to evaluate the specific requirements of your application. Consider factors such as the actuator's torque output, response time, and compatibility with various control systems. Additionally, assessing environmental conditions is crucial, as certain actuators may perform better in extreme temperatures or corrosive environments.

Tips: Always ensure that the actuator matches the valve size and type. Regular maintenance and checks can help prevent unexpected failures and extend the life of both the actuator and the valve. Furthermore, investing in a high-quality actuator can lead to significant improvements in efficiency and reliability in the long run.

Key Factors Influencing the Selection of Actuators

When selecting ball valve actuators for industrial applications, several key factors significantly influence decision-making. One primary consideration is the actuator type, which can be categorized into electric, pneumatic, and hydraulic actuators. According to a recent industry report by MarketsandMarkets, the electric actuator segment is projected to grow at a CAGR of 6.4% from 2023 to 2028, driven by advancements in automation and energy efficiency. Each type offers distinct advantages; for instance, electric actuators are preferred for their precision and operational efficiency, while pneumatic actuators are favored for rapid response times in high-speed applications.

Another crucial factor is the torque requirements of the valve being used. Proper torque selection ensures that the actuator can effectively operate the valve under varying pressure conditions. Industry analyses show that nearly 30% of actuator failures stem from incorrect torque specifications, leading to operational inefficiencies and increased maintenance costs. Furthermore, the environmental conditions where the actuators will be installed, including temperature variations and exposure to corrosive substances, should also guide actuator selection. In harsh environments, actuators with robust housing and seals are essential to maintain performance and prolong service life. Understanding these factors is vital for optimizing the efficiency and reliability of industrial processes utilizing ball valves.

Top 10 Ball Valve Actuators for Efficient Industrial Applications

Top 10 Ball Valve Actuator Models and Their Features

When selecting a ball valve actuator for your industrial applications, it’s essential to understand the varying models and their unique features.

Electric actuators are widely valued for their precise control and low maintenance needs, making them suitable for automated systems.

Pneumatic actuators, on the other hand, are favored for their rapid operation and ability to handle high cycle rates, which is beneficial in processes requiring quick response times.

Hydraulic actuators provide powerful torque, ideal for larger valves or when dealing with high-pressure conditions.

Tips: Consider the operational environment when choosing an actuator type. For instance, environments with limited space might benefit from compact electric actuators, while locations requiring high-speed operations could favor pneumatic options. Additionally, ensure the actuator's compatibility with the valve and the overall system to optimize efficiency and reduce operational issues.

Another crucial feature to evaluate is the actuator’s control system. Some models offer advanced controls for integration with smart technologies, enabling real-time monitoring and automation.

Look for features such as feedback systems, position indicators, and fail-safe options to enhance reliability and safety in your processes.

High degree of automation can lead to significant efficiency gains, but it is essential to balance technology with user-friendliness to maintain operational simplicity.

Comparative Analysis of Efficiency and Performance in Applications

In industrial applications, the efficiency and performance of ball valve actuators play a critical role in optimizing operational processes. A comparative analysis of various actuators reveals significant differences in their design, functionality, and energy consumption. Electric actuators, for instance, offer precise control and require minimal maintenance, making them ideal for applications needing high reliability and accuracy. Conversely, pneumatic actuators are known for their rapid operation and powerful output, which suits applications with frequent cycling and high torque demands.

When evaluating efficiency, one must consider factors such as response time, energy usage, and compatibility with existing systems. Hydraulic actuators stand out in high-pressure scenarios due to their robust performance, while smart actuators equipped with advanced control systems further enhance operational efficiency through real-time monitoring and data analysis. The choice of actuator depends heavily on the specific requirements of the industrial application, including the medium being controlled, the operating environment, and the need for automation. Overall, understanding these comparative aspects guides industries toward selecting the most effective ball valve actuators, ultimately leading to improved efficiency and enhanced productivity.

Related Posts

-

Unlocking Efficiency: How Ball Valve Actuators Revolutionize Industrial Automation Systems

-

Understanding the Importance of Air Valve Types in Industrial Applications

-

2025 Top 10 PTFE Valves for Chemical Processing with 30 Percent Improved Durability

-

2025 Top 10 Air Valve Innovations You Must Know About

-

Understanding Industry Standards for the Best Actuator Valve and How to Choose the Right One

-

Ultimate Checklist for Choosing the Right PTFE Valve for Your Industrial Needs